Top 7 Scaffolding Questions With Answers

Comments Off on Top 7 Scaffolding Questions With Answers

Finding the right help can be tough. There are several types of scaffolding, and depending on its height, an engineer’s input might be necessary to ensure you choose wisely. Safety is another crucial aspect to ponder. Thus, landing the correct scaffolding aid can significantly affect your project’s timeline and success. We’ve answered some regular scaffolding questions to ease your thought process for your project and aid in choosing an appropriate service. If you still have questions after going through these, we’re here to help you with your scaffolding questions.

Trending 7 Scaffolding Questions Asked

1. What Are Scaffold Weight Limits?

When it comes to construction and renovation projects, scaffold weight limits play a crucial role in ensuring safety and efficiency. Scaffolding is a temporary structure that supports workers and materials during building work, maintenance, or repairs. It’s essential to comprehend its use, limitations, and regulations to ensure a smooth and secure construction process. Scaffolding accessories distributors in the USA can provide crucial components to enhance scaffold functionality and safety.

2. What Is Scaffolding Used For?

Scaffolding is like a big, strong set of metal bars and platforms that people use when they’re building stuff, like buildings or fixing things up. It’s made to be strong and safe, kinda like a steel ladder design, so workers can stand on it, move around, and reach high places easily. It helps them do their work up high without worrying about falling down.

3. Can I Still Access My Building With Scaffolding?

Typically, scaffolding is designed to allow access to the building or structure being worked on. However, the exact access points depend on the scaffold’s design and placement. Professional scaffolding contractors consider accessibility when erecting scaffolds to ensure minimal disruption to building access.

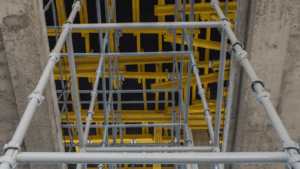

So, if your building has a cuplock scaffolding system, accessing it might be possible even with the scaffolding in place. The cuplock system uses special joints that allow for easy access points, kind of like using specific puzzle pieces that fit together neatly. With this system, there are usually built-in ways to create pathways and platforms, making it safer and easier to get around your building, even when it’s covered in scaffolding.

4. Do I Need To Apply For Permit?

Regulations regarding permits for scaffolding vary based on location and the specific project. In many cases, especially for larger or commercial projects, a permit may be required before erecting scaffolding. It’s crucial to check local regulations and obtain necessary permits to avoid legal complications.

5. Can Scaffolding Be Erected On Uneven Ground?

Yes, scaffolding can indeed be set up on uneven ground. It’s crucial to have scaffolding with adaptable parts. This way, you can tweak the scaffold bits to sit perfectly on your work area’s terrain. The often-used tube-and-clamp type scaffolds have such adjustable parts. These are a popular choice for uneven terrain due to their adaptability to various heights, sizes, and the safety they provide on such ground. Furthermore, appending spigots to fixed stands is significant. This process guarantees the pillars’ strength and stability, even on an uneven surface. Scaffolding can be set up on uneven ground with proper planning and the use of specialized systems like the ring lock scaffolding.

6. How Do You Manage Health & Safety?

Health and safety are paramount in any construction project involving scaffolding. Contractors and workers must follow strict safety protocols, including regular inspections, proper use of safety gear, and adherence to established safety guidelines. Additionally, selecting reputable scaffolding accessories distributors in the USA ensures the use of high-quality, safety-compliant equipment.

When people are building something using scaffolding (those temporary structures made of metal poles and planks), it’s super important to keep everyone safe and healthy.

The folks in charge (contractors) and the workers need to be really careful. They have to follow specific rules to make sure everyone stays safe. That means checking the scaffolding regularly, using the right safety equipment, and doing things the way they’ve been told is safe.

And when they’re getting the equipment they need, like parts for the scaffolding, they should pick trustworthy companies in the USA. That way, they can be sure they’re getting really good stuff that’s been checked for safety.

7. Do You Require Scaffolding Services?

Looking for really good scaffolding? AAIT has got you covered! We’re the people you can trust for all your scaffolding needs. Whether you’re building, fixing, or just taking care of things, our team is super good at what they do and makes sure everything is safe.

We hope these scaffolding questions will help you to build your scaffolding.

Why Choose AAIT For Your Scaffolding Distributors In the USA ?

At AAIT, we know how crucial it is to start with a strong base for any project. That’s why we give you the best scaffolding that’s even better than what you expect.

- We’re pros and always do a great job

- We make plans just for your project

- Safety is super important to us

- We use cool new ways to do scaffolding

- We’re here for you whenever you need us

Get in touch with us now for AAIT Scaffolding Services! Let’s make your project awesome together. If you want to purchase Scaffolding in Houston, scaffoldssupply.com is also well known place to Buy Scaffolding Online in USA at very reasonable cost.

Download

Download