Types of Scaffolding in Construction

In the present time, a scaffold offers a stable platform for carrying out construction tasks. The overall structure also enables workers to move across different sections. Additionally, the scaffold offers comfort while working for a pretty long time. But, are you still confused on which scaffold to use? Well, check this article to know more about the types of scaffolding in the construction sector.

Single / Brick Layer Scaffolding

Whenever a structure has to be built with bricks, a single scaffolding is used. While the scaffold is quite stable, it helps workers to do tasks at different levels. Usually, it comprises many components like ledgers, standards, and more. While the standards have to be 2 m apart, the ledgers have to be placed 1.2 m away. Additionally, the workers attach the putlogs to the ledgers. Mostly, these are placed at an interval of around 1.2 m.

Double / Independent Scaffolding

Now, when the structure has to be built using stones, then the workers will use double scaffolding. As stones are hard, it is tough to drill holes. Hence, the scaffold is made stronger with two rows of bars. The first row is always at a distance of 20 cm from the wall. But, the other row is 1 m away from the row that has already been set up. A bit later, putlogs are placed for supporting both the frames.

If you’re seeking a scaffold as per your needs, then don’t hesitate to contact a leading scaffolding equipment supplier.

Cantilever Scaffolding

During maintenance work, this kind of temporary structure is employed. In this structure, the horizontal bars are firm due to the support of cantilever beams. Moreover, workers use the scaffold when it’s hard to reach certain areas. They no longer have to bother about ground-based supports. Owing to the entire design, workers can expect less interference from people walking along a street.

Suspended scaffolding

Among the types of scaffolding, these are quite efficient when used for tasks on tall buildings. They consist of platforms suspended from overhead supports. Mechanical hoists or ropes are used to set up this scaffold. Once individuals use the structure, they can access high levels easily. As these can be adjusted, they are useful for tasks like facade repairs, painting, and window cleaning.

Ladder / Trestle scaffolding

In such a type of scaffold, the tripods support the working platform. While these are compact in nature, they are useful for less intensive tasks. Most of the time, workers erect these inside a room. They use it while painting walls or doing tasks related to repairing. As the legs can be adjusted, they can be altered based on the scenario.

Mobile Scaffolding

As you can figure out by the name, these scaffolds have wheels. Hence, workers can move the structure when there’s a need. For instance, if they have to paint many walls, then they prefer using the scaffold. Besides, it’s not complex to assemble or dismantle the structure entirely. It can also be set up at different heights.

Tube & Clamp Scaffolding

Under the types of scaffolding, these comprise couplers and tubes. These are also widely used as they can be assembled with minimal effort. The workers can also place the vertical bars in any position. So, if they want to erect an odd scaffold, then this type is ideal. The structure can be either erected for irregular buildings or within a plant. The diagonal tubes may also be used to increase stability. Workers establish a secure connection using couplers or swivel clamps.

System Scaffolding

At times, people may call these scaffolds as modular scaffolds. However, workers must make sure that they erect the scaffold in a nice way. This has to be considered because the bars are already designed.In addition, workers don’t have to be skilled in erecting this scaffold. This is because the connectors’ locations are fixed.

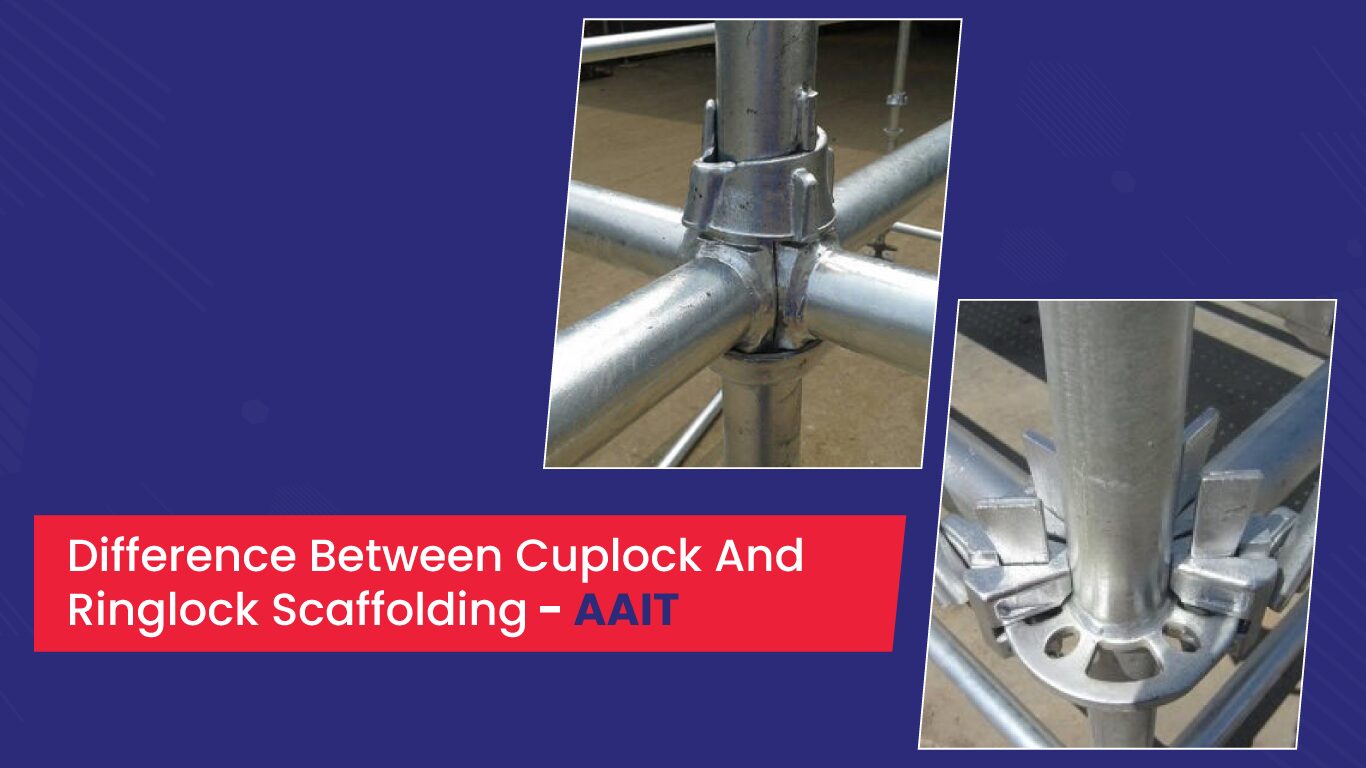

Cuplock scaffolding

Cuplock scaffolds are modular structures known for efficiency. These are also easier to assemble at the construction site. Once set up, the various components are connected with unique cuplock fittings. Because of this, the scaffold is quite strong. Furthermore, the modular design offers flexibility in handling diverse projects.

Kwikstage scaffolding system

Owing to their stability, these scaffolds are widely used in the construction sector. Just like cuplock scaffolding systems, these have vertical and horizontal bars. But, these differ from other types of scaffolding due to the locking system. These have V-shaped fittings in place of cup-shaped locking mechanisms. Once the ledgers fit into the exact positions, the system is secured. In addition, stability is complemented by transoms. These are used to link the outer bars with the inner ones.

Staircase Tower

Staircase towers are mainly used with an aim to use the main platform. Once you observe the scaffold type, it appears like a staircase. Therefore, workers can carry tools safely by climbing the stairs. This is a safer way than using a ladder. However, to enhance its strength, manufacturers may use special components.

Frame & Brace Scaffolding

Known as sectional scaffolding, the frame and brace scaffold is most common at sites. Apart from being versatile, the scaffold is easy to use. Most of the time, people set up this structure in one or two levels. But, because of the modular frames, these can be extended. In fact, workers can access several levels when it’s used in large-scale projects.

Mast Climbing Scaffolding

Synonymous to suspended scaffolds, these are not hung using wires. But, these are quite strong when compared to other types of scaffolding. A fixed mast structure also enables them to descend or ascend along the scaffold. Moreover, the best part is that these scaffolds can be extended to reach multiple floors. They are also useful, especially when there’s less ground area.

Shoring

Shoring systems serve as a structure to support something that’s permanently set up. This may include a bridge or a building. Primarily, the structure as well as the formwork keep liquid concrete in place. Thus, the concrete solidifies till the time it supports itself.

Other forms of scaffolds

Besides the above scaffolds, equipment is used to offer a stable platform. Such equipment is manually driven or may run on an electric current. It is quite useful for short term projects covering a small region. Under these, you will come across scissor lifts, cradle scaffolds, and more.

FAQ

1. What are the 6 types of scaffolding?

Single, double, cantilever, suspended, Kwikstage and Cuplock are the 6 types of scaffolds.

2. What are the 3 types of scaffolding?

Single, double, and suspended scaffolding are the 3 types of scaffolds.

3. What are the three basic types of scaffolds in the construction industry?

Among the various types of scaffolds, suspended, double and single scaffolding is mainly used in the construction domain.

4. What is the most common type of scaffolding?

Ringlock scaffolding is the most common type of scaffold. However, workers may use single and double scaffolds based on the intended purpose.

5. What is a class 4 scaffold?

Class 4 scaffold is normally known for sustaining heavy activities. This scaffold is useful while storing material or carrying out masonry work.

Conclusion

Finally, if you can’t decide, then you can contact AAIT Scaffold. Through the years, we have been the leading scaffolding equipment supplier in the US. Through the years, we have earned a reputation for offering reliable scaffolding solutions. While we meet diverse needs of industries, we always focus on quality.

Download

Download