Everything You Need to Know About the Cuplock Scaffolding System

Comments Off on Everything You Need to Know About the Cuplock Scaffolding SystemCuplock Scaffolding System is a framework placed outside the building to allow builders access to the emerging structure. Once the building is independent and supports itself, the scaffolding is removed. It aids in the construction process, maintenance, repairs of buildings, and other concrete structures.

There are different types of scaffolding systems like- Tube and coupler components, modular system scaffolds, timber scaffolds, bamboo scaffolds, etc. The most popular type of system scaffold is the modular system scaffold, which consists of verticals and horizontals to create a framework. These systems are easy to construct and support heavy weights.

The modular scaffolds are segmented into three systems: the cuplock system, the ringlock system, and the kwickstage system. Amongst these three, the cuplock system is the most popular one. It consists of prefabricated individual components along with a unique locking system, which makes it easy to use and robust enough to bear weights.

In this article, we shall walk through all the aspects and benefits of the cuplock scaffolding system.

What is the cuplock scaffolding system?

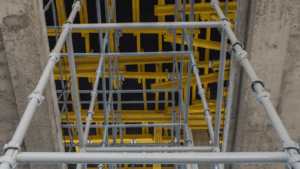

This system is characterized by a unique locking mechanism that links four bars together at a central joint. This makes it easy to set up and very economical. The framework is built from prefabricated horizontal and vertical bars. It also incorporates walkways, which makes this system more accessible.

This system reduces assembly time and provides versatility, along with super strength to support the work crew.

Components of the Cuplock System

1. Standards/Verticals

These are the prefabricated verticles that are fixed with lower cups at the bottom and rotating cups on the top. These can securely hold up to four components together. Cuplock verticals are available with and without spigots, increasing the adaptability of the Cuplock scaffolding system.

2. Ledgers/Horizontals

Cuplock ledgers provide horizontal support to the system. They fit into the vertical tubes, ensuring a solid assembly. Horizontals can also be used as guardrails in the staircase tower. cuplock ledger 1.5 mtr weight these have forged blade ends that make them easy to assemble.

3. Universal Jack

This is used as an adjustment part at the bottom or top of the system structure. It can accommodate different ground levels that are adjustable by up to half a meter, ensuring a leveled structure. The Universal Jack is used in conjunction with baseplates, adapters, and foreheads. They support the entire load of the structure.

4. Transoms

These provide intermediate support to the scaffold boards. They connect the inner and outer horizontal ledgers and serve as a locking mechanism to keep them in place. To prevent the ledgers from dislocating, each end of the intermediate transom is designed like a jaw.

5. Board brackets

These are used to support two to three boards beyond the interior of the framework, increasing the span of the working platform. The exterior edge of board brackets has a cup joint in which a cuplock ledger can be fixed. It also has a socket that is used as a handrail post support.

6. Other accessories

These include spigot pins, single board support, Clamp Brace, steel toeboard, handrail posts, swivel face brace, castor wheel, hook decks, safety gates, etc. that add up to the adaptability of the system.

Benefits of using a cuplock scaffolding system

1. Easy to use

This system is a flexible and adaptable system. It can be used to build different structures for construction, refurbishment, or maintenance projects. Its application in any type of industry, like refineries, energy production, chemical plants, aircraft, shipyards, etc., makes it more popular. It is used to build facade scaffolds, loading bays, curved structures, birdcage structures, mobile towers, staircases, shoring structures, etc., which makes it more versatile.

2. Light in weight and safe

This system is light-weighted and palletized. This makes them easy to transport and store. They are also durable as they feature a galvanized surface. This surface protects them from corrosion. The Cuplock system eliminates the use of diagonal braces, which makes it safer to navigate. It also accommodates staircases and ladder safety gates, which makes it the safest scaffolding system.

3. Easy to install

The Cuplock scaffolding system‘s node-point locking device is one of its distinguishing characteristics. A single vertical tube may be connected to four horizontal tubes with this apparatus. Furthermore, no loose bolts, wedges, or clips are required to secure components to the node-point, making this scaffolding easier and faster to construct.

Structures constructed using the cuplock scaffolding system

The cuplock system is versatile and flexible enough to accommodate different structures depending on project requirements.

1. Curved structures

Because the horizontal tubes can be locked into the vertical tubes from practically any angle, the scaffolding framework may be used to build curved buildings. The regular arrangement of transoms and ledgers necessitates simple changes that can assist in the creation of internal or exterior curves in the construction. These curving constructions are made up of trapezoidal and rectangle-shaped bays.

2. Loading Bays

These need a very sturdy platform capable of supporting large palletized items. This one-of-a-kind platform has a flexible arm gate that moves up and down to keep the operator safe from the platform’s edge. The Flexi arm connects the panel to the Cuplock framework; it may be lifted above while the temporary barrier is automatically lowered. When the Flexi arm gate lifts, a safety barrier drops automatically in front of the worker to provide continuous protection.

3. Staircase towers

The cuplock framework enables the construction of staircase towers on-site, allowing employees to travel effortlessly from level to level. These towers need the use of stairway components that are particularly constructed for this purpose and provide employees with a safe and efficient method to ascend and descend. Staircase towers are simple to build and save a lot of time and energy.

Summary

The Cuplock system is a one-of-the-kind system that is versatile and suits every construction site. It is the safest and easiest means of erecting a strong system scaffold.

AAIT Scaffolds is a cuplock system manufacturer and cuplock distributor in the USA. Our products are certified and made from best-in-class low alloy structural steel and come with a hot-dip galvanized finish.

Download

Download