Difference Between Cuplock and Ringlock Scaffolding—AAIT

Comments Off on Difference Between Cuplock and Ringlock Scaffolding—AAITIn today’s construction domain, many contractors consider building a scaffold for performing diverse tasks. These not only offer stability but also keep the workers secure. Individuals no longer have to worry about accidents. But do you know anything about ringlock or cuplock scaffolding? This article will provide you with a comprehensive overview. This article will guide you through the various types of scaffolds available.

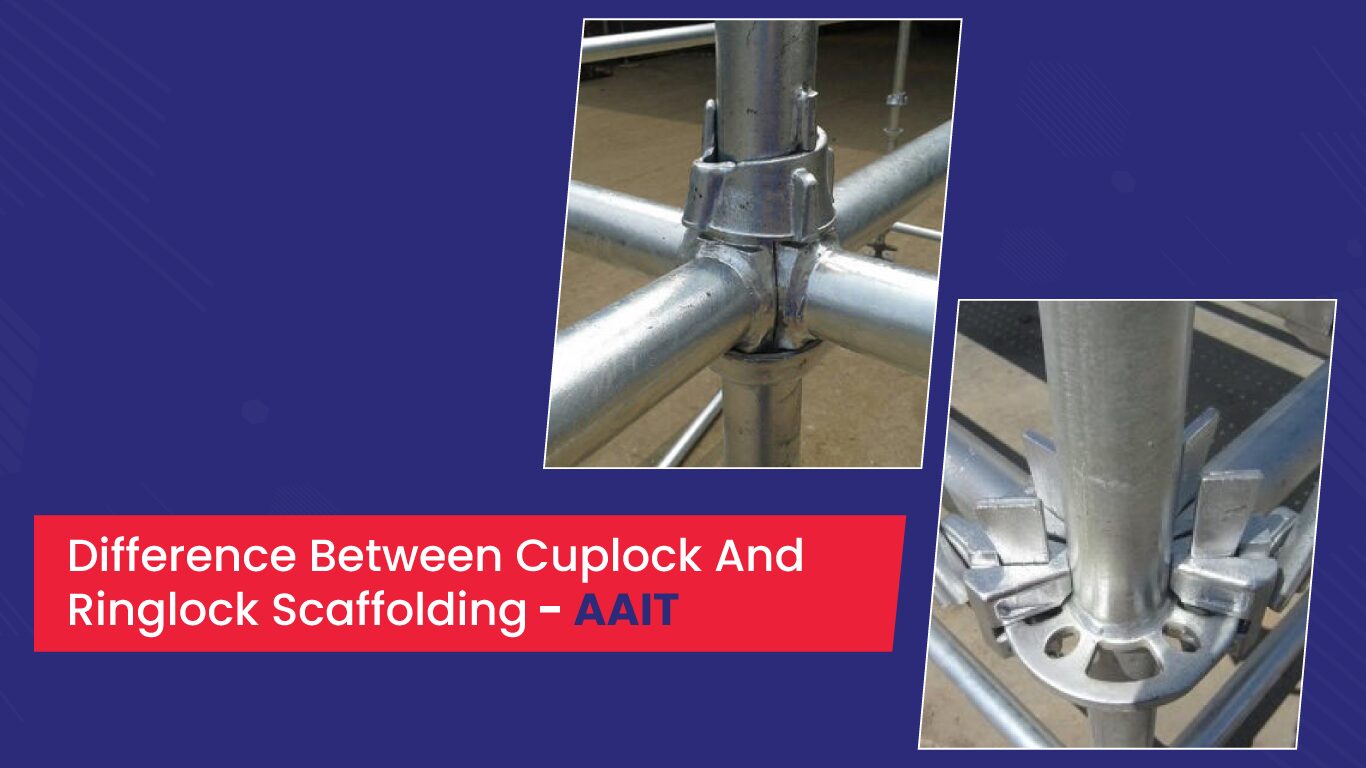

Difference between cuplock and ringlock scaffolding.

What is Cuplock scaffolding?

Cuplock scaffolds are nothing more than modular systems known for their versatility. These have node-point connections, with horizontal and vertical bars secured through cup-like connections. Without bolts and nuts, workers can easily assemble the scaffold. Moreover, as these scaffolds adapt to different configurations, they are suitable for diverse construction projects. Scaffolds are also becoming more popular due to their reliability and durability.

Advantages of Cuplock Scaffolding

Cuplock scaffolding structures offer many benefits in the construction sector. Let’s check out the advantages in detail.

Allows for quick assembly.

When you use cuplock scaffolding components, they are easier to assemble. Because the structure is modular, workers can quickly install it. This makes them suitable, especially when productivity is the prime concern.

Versatility

You can quickly adjust Cuplock scaffolding to meet the needs of the project. This aspect makes it ideal for projects that involve building intricate properties.

Withstanding high loads

Sustaining a large number of workers is one of the benefits of cuplock scaffolds. This capability is beneficial when workers have to use a stable and secure structure for diverse tasks.

Stability

As contractors approach the scaffolding equipment supplier, they prefer using such scaffolds. The wedge-locking mechanism ensures utmost stability, thereby mitigating the risks of unexpected accidents.

Ultimately, such structures are cost-effective. Workers can disassemble and assemble the structure with ease, which reduces labor costs. Furthermore, their value lies in their versatility across various projects.

What is Ringlock Scaffolding?

When you closely examine ringlock scaffolding, you’ll notice that projects widely use it because of its efficiency. While workers use them, the rosette-type connectors help to quickly connect the vertical and horizontal parts. Individuals can also move ahead with different configurations to suit the project requirements. These are quite strong, so they can provide stability and support for maintenance and renovation projects.

Advantages of Ringlock Scaffolding

Ringlock scaffolding, just like cuplock scaffolding, have their own advantages when used on construction sites. Let’s quickly check out how such scaffolds can benefit workers.

Diverse Applications

The design of Ringlock scaffolds allows for the construction of complex structures. While you consider these, you can set them up to construct mobile towers or other unique buildings.

It supports simple assembly.

As such, scaffolds provide a sturdy structure for performing tasks, making them easy to set up and disassemble. This, in turn, saves considerable time, allowing workers to spare time for the tasks at hand.

Stable and Flexible

These scaffolds provide contractors with a completely optimized structure. By using the notches, workers can set locks at different angles and with precise alignment.

Capacity to sustain load

The overall design of these scaffolds allows them to support a significant weight. Therefore, heavy-duty construction tasks utilize these scaffolds. Such structures’ flexibility also helps to carry out lumber formwork.

Beyond everything else, ringlock parts are light in weight. So, when workers are planning to erect a scaffold, they can carry the parts with ease. Moreover, the parts occupy less space, so storage is not a problem.

Difference between Cuplock and Ringlock

Are you still confused about the type of scaffold you should erect? Well, let’s check out the difference between cuplock and ringlock scaffolding.

In the case of cuplock scaffolding, you will notice vertical bars that have connectors. Workers assemble this scaffold by attaching the horizontal columns to the cup-shaped connectors. In contrast, ringlock scaffolds have vertical columns with rings at certain places. The rosettes receive the horizontal bars whenever they need to connect.

As far as assembly and dismantling are concerned, ringlock scaffolds have a rosette-based locking mechanism. In addition to flexibility, these enable workers to adjust the structure whenever needed. Therefore, you can consider this scaffold when you connect with the scaffolding equipment supplier.

Now, with regards to the load-bearing capacity, both scaffolds are strong. Ringlock scaffolds, on the other hand, are superior to cuplock scaffolding because of the different rosette positions. This helps to adapt to the project’s needs and distribute the load evenly.

Next, workers utilize ringlock and cuplock scaffolds in various settings. When you observe the construction of dams or bridges, you will notice that workers commonly use ringlock scaffolds. But for complex construction projects, people prefer using cuplock scaffolds.

Ultimately, the type of scaffold you need to erect is entirely up to you. But, before proceeding ahead, you should be aware of the project requirements and complexity of the structure. Getting in touch with an experienced professional will further help you determine the type of scaffold.

Conclusion

In conclusion, we want to emphasize the importance of understanding these types of scaffolds. As a contractor, you can think about setting up a cuplock scaffold for straight structures. However, when starting tasks for complex structures, it is preferable to use a ringlock scaffold. Above all, both scaffolds provide safety, even when many workers have climbed them.

If you’re looking for a ringlock or cuplock scaffold, please contact AAIT Scaffolds. You can also contact us for high-quality scaffold accessories.

Steel Scaffolding vs. Aluminum Scaffolding (AAIT)

Comments Off on Steel Scaffolding vs. Aluminum Scaffolding (AAIT)When you’re moving ahead with a construction project, it can be confusing what type of scaffold you must select. But when you’re concerned about safety, you can choose between steel and aluminum scaffolds. In this article, we shall learn about steel scaffolding vs. aluminum scaffolding based on their uses. You will also know about the benefits of each scaffold.

Strength of Steel Scaffolding

For centuries, steel scaffolding has been known for its strength. Steel columns also increase strength because they transfer forces to the ground. Additionally, the horizontal bars form a lattice with the vertical columns. For additional support, workers also use transoms at every level. Couplers also enhance strength by connecting the tubes perpendicular to one another. Let’s check out whether an aluminum scaffold is strong.

Strength of Aluminum Scaffolding

Aluminum scaffolds have strength even when they are light in weight, just like steel scaffolds. This enables quick setup and reduces labor costs. Despite being light, the structure is robust and durable. It always has the capability of supporting heavy loads. In addition, properties like corrosion resistance ensure longevity even in extreme outdoor conditions. Furthermore, the entire structure is flexible in design to suit diverse project needs.

Weight of Steel Scaffolding

Compared to aluminum structures, steel scaffold components weigh from 20 to 40 kg. However, because the entire steel structure is heavy, its weight may exceed that of an aluminum scaffold. Furthermore, factors such as design and configuration can contribute to the weight difference. This nature, therefore, makes it suitable for contractors executing large construction projects.

Weight of Aluminum Scaffolding

The overall weight of these scaffolds varies depending on the configuration and design. As the metal is lighter than steel, the components weigh between 15 and 30 kg. However, once set up, a scaffolding structure can weigh several hundred kilograms. Even then, the structure’s weight will depend on the height and the width. This nature allows for easy movement of such scaffolds to various locations. This makes it ideal when workers have to carry out maintenance-related tasks.

Applications of steel scaffolding

Long-term and temporary projects typically use steel scaffolding. Workers can carry out tasks like setting up windows and laying bricks because these offer support. Apart from this, workers can use the scaffold for repair work on tall buildings. Bridges or industrial areas undergoing repairs can also utilize the scaffolding. Additionally, staging setups heavily utilize steel scaffolds. Because they are adjustable, they can serve a variety of purposes.

Applications of Aluminum Scaffolding

People often use aluminum scaffolding for various applications. These are ideal for maintenance work and construction in a residential area. Because the structure is lightweight, it’s ideal for projects that require relocation. Additionally, event planners use the scaffold structure for staging purposes. Event to their resistance to wear and tear, event planners also prefer using aluminum scaffolds. These are usable even in extreme outdoor conditions.

The advantages of steel scaffolding

When you set up steel scaffolding, it offers many benefits.

Durability

Steel scaffolding is strong and can support heavy loads. Hence, contractors can think about this scaffolding for large-scale projects.

Safety

While using steel scaffolding, workers can carry out tasks on a stable platform. This mitigates the likelihood of accidents.

Versatility

Steel scaffolds are versatile by nature. This implies that they can adapt to their specific requirements.

Cost-Effective

Even though you might have to invest a lot, steel scaffolds are cost-effective. They always last for a long time in an outdoor environment.

Easy to assemble

You can quickly set up and disassemble such scaffolds. This helps meet the timelines of construction projects.

In the end, we can build this type of scaffold to perform tasks high above ground level.

Benefits of Aluminum Scaffolding

Aluminum scaffolding offers several advantages over steel scaffolding.

Lightweight

Aluminum’s lighter weight enables easy dismantling of the components. When moving scaffolding to different locations, this is useful.

Resistance to corrosion

Aluminum components don’t wear out easily. Hence, the scaffold is ideal for construction sites. In the future, workers also don’t have to worry about maintenance.

Always Durable

Even though the scaffolding equipment suppliers’ parts are lightweight, they can withstand heavy loads. They also keep the structure stable when individuals are working.

Adjustable

Aluminum scaffolds are adjustable at any time. This allows the workers to meet the requirements easily.

Resistance to the weather

Rain or high temperatures do not deteriorate aluminum components. This makes them suitable for diverse projects.

Conclusion

Finally, you can decide on the scaffolding structure based on the project’s needs. You can also erect scaffolding depending on the individuals working at the construction site. The budget should also be considered before choosing between an aluminum and steel scaffold.

Still searching for high-quality scaffolding accessories? Get in touch with AAIT, the leading scaffolding equipment supplier based in the US.

Scaffolding Braces | Benefits – Importance – Types

Comments Off on Scaffolding Braces | Benefits – Importance – TypesWhen workers are building a scaffolding structure, they always need to use braces. These offer many benefits beyond stability. Proper placement of the braces also preserves the integrity of the scaffolding structure. But do you really know the different types of scaffolding braces? In this article, you will know more about scaffolding braces and their types.

What Are Braces in Scaffolding?

In the construction domain, it’s important to ensure stability while using the scaffold. Hence, when workers assemble the scaffold, they use braces. These refer to connections that hold the scaffold components in a certain position. If you fail to set up the braces, the scaffolding structure becomes weak and unsafe for use. Let’s check out the different types of scaffolding braces.

Scaffolding Bracing Types

When you encounter braces at the market, you will notice a variety of types. Here are some of the braces commonly used by workers.

Diagonal Braces

Such braces place the scaffold tube diagonally with the vertical and horizontal members.

Cross Braces

Cross braces occur when the tubes are placed diagonally and cross one another. The center joins the members as they form an X shape.

Longitudinal Braces

Elements positioned along the scaffold’s length are known as longitudinal braces. They connect the vertical posts with one another to ensure stability.

Plan Braces

The scaffolding structure positions these elements horizontally and diagonally within its plane. Apart from offering additional stability, these elements avoid lateral motion during tasks.

Transverse Braces

Traverse braces are components placed diagonally across the scaffold’s width. These provide lateral stability because they connect vertical posts on opposite sides.

Dog-Leg or Zigzag Braces

Workers arrange zigzag braces in a zigzag pattern. These often connect the vertical posts on opposite sides of the structure.

Requirements of Scaffolding Bracing

While workers are setting up the scaffold, it’s important to ensure stability and safety. Here are some requirements for bracing.

>> Before placing the braces, the material should be strong to withstand loads. Using cross or diagonal braces can also help to ensure stability.

>> As per OSHA standards, it’s necessary to use braces with a height up to 26 feet. This is the standard for a three-foot distance.

Bracing requires adherence to specific design guidelines. Professionals should also calculate the load-bearing capacity.

Workers must follow certain instructions when installing braces. Placing the braces at the correct angles also helps to enhance stability.

Scaffolding Braces for Sale

When you’re looking for braces, an online search can help you find suitable ones. Moreover, you will also find braces in popular online stores. If you can’t afford to buy the braces, then consider ones made in China. You can easily find such types of braces on websites like AliExpress, Alibaba, and more.

What is the purpose of cross-braces in scaffolding?

Cross braces help prevent the vertical members from swaying. Once the braces are in place, the scaffolding structure remains upright at all times. Moreover, cross-bracing prevents accidents that may occur due to dwanging or swaying.

Scaffolding Cross Brace Sizes

The size of cross braces varies depending on the scaffolding structure. Moreover, workers will have to use braces of appropriate sizes based on the construction project. However, the standard sizes of cross braces include 8’ x 4’, 10’ x 4’, 7 x 3’/4’, and 10’ x 27.75”. However, many suppliers will provide braces in larger than usual sizes.

Cross Scaffolding Braces Price

The overall cost of scaffolding braces will vary depending on the dealer. However, braces are typically priced between $10 and $35. If you purchase a large quantity of braces, the cost will be more affordable. On the other hand, when you consider buying braces from Chinese manufacturers, the rate is lower.

How can I choose the best scaffolding braces available in the market?

Many factors have to be considered before buying scaffolding braces. Let’s check them out one after the other.

Manufacturer

Firstly, you need to consider a supplier before selecting the braces. Even when they deal with the same range of braces, they may differ.

Price

Price is another aspect to consider before making a purchase. If the braces are affordable, then it doesn’t mean they are poor in quality. But high prices mean you must check braces durability.

Material

The material of the braces also matters most before making a purchase. If you’re concerned about strength, then go for galvanized steel braces. However, you should consider aluminum braces as they remain unaffected by chemicals. The outdoor environment around aluminum braces also doesn’t oxidize them.

Safety

Lastly, ensure that the braces are safe to use. This relates to the scaffolding structure’s setup and worker safety.

Where can you purchase the best scaffolding braces?

When you’re looking for scaffold braces, you’ll find many companies worldwide. However, for the best braces, you should connect with organizations in Europe and the US. Way ahead, many organizations get in touch with Chinese companies for manufacturing the braces.

If you’re looking for good-quality braces, then you can get in touch with AAIT Scaffolds.

Benefits of Choosing AAIT’s Scaffolding Braces

When you approach AAIT for scaffolding braces, we use high-quality material that is resistant to environmental conditions. We ensure that our braces meet safety standards for various construction projects. Moreover, we offer different types of braces to suit the project requirements and the scaffolding configurations.

Download

Download