What is Kwikstage Scaffold and Its Benefits?

Comments Off on What is Kwikstage Scaffold and Its Benefits?

When you’re executing a construction project, a robust scaffold system is always essential. These offer a safe working platform and reduce the risk of unexpected accidents. They provide support for workers when they are busy with their tasks. Moreover, the scaffold system also drives the workflow by provisioning access to different areas. Overall, the scaffold system ensures the safety and success of construction projects. With scaffolding set up at suitable locations, workers can work more efficiently, which enhances productivity. In this article, we will cover more about Kwikstage scaffolds and how they can be beneficial at construction sites.

What is Kwikstage Scaffold?

Kwikstage Scaffold is a modular scaffolding system used in construction projects. Most often, such a scaffolding structure is set up for intricate building front ends. These are ideal when usual scaffolding is unavailable. Kwikstage scaffolding includes horizontal tubes, steel boards, bracing, and vertical posts.

As such scaffolds come under modular scaffolding, they can be assembled without using special tools. Moreover, the workers can alter its shape depending on the building. Adaptability to different configurations also makes these ideal for a vast range of construction projects. Workers can use the scaffolding system for large scale structures and small-scale projects. Once the scaffolding system is erected, it offers stability even when workers have to work at a certain height from ground level.

What material is Kwikstage?

Kwikstage scaffold is basically made of high-quality steel. Manufacturers choose steel because the metal is resistant to corrosion, durable in nature, and known for strength. These properties make them ideal for construction projects where safety is the main concern. However, you may also come across such types of scaffolding systems made from Aluminum. As far as the Kwikstage scaffolding components are concerned, these are also manufactured from high-quality steel to ensure reliability. In addition, the platforms or steel boards that workers use often provide a sturdy and robust surface when workers are involved in different construction tasks.

What are the benefits of Kwikstage Scaffold?

Many reasons make Kwikstage Scaffold suitable for various building tasks. Here are some of the benefits of setting up the Kwikstage scaffold.

Versatility

Such modular scaffolding systems are extremely adaptable and can be molded to suit different construction projects. The modular design offers flexibility in assembly, and hence it’s suitable for a vast range of applications.

Easy to Assemble

As soon as workers start using the scaffold, it can be assembled quickly and with ease. Workers no longer have to use specialized tools for the setup. This reduces time and labor expenses, thereby improving efficiency.

Safety

These scaffolds are designed to meet certain safety standards. Therefore, they offer a safe and stable platform even when the tasks have to be performed high above the ground. Due to sturdy guardrails, locking mechanisms, and toe boards, workers are unlikely to meet with sudden accidents.

Stability

Designed from high-quality steel, these scaffolds offer a lot of support for workers. This not only ensures stability but also structural integrity at the construction site. Even after regular use of the scaffolds, the structure doesn’t collapse due to the weight of the workers.

Durability

Such scaffolds are known to stay intact for a long time. The different parts are made from steel that is resistant to corrosion. Moreover, the modular scaffolding system doesn’t get affected by inclement climatic conditions.

Adaptability

This scaffold can be easily adjusted and modified to accommodate changes in the construction project, such as alterations in height or configuration. This makes it a versatile solution for evolving construction needs.

Cost-Effectiveness

As compared to usual scaffolding systems, the investment costs for such scaffolds might be high. However, these scaffolds help to save costs in the long run due to their reusability and durability.

Compliance with standards

Whenever such scaffolds are designed, they surpass safety standards and regulations. Hence, workers and contractors don’t have to worry about anything when they carry out numerous construction tasks.

Finally, you should consider many factors before choosing Kwikstage scaffolds. Initially, you have to evaluate the scope of the construction project to determine its configuration. You should also ensure that the scaffolding system can sustain anticipated loads. Before considering the scaffold system, you also have to contact a reputable supplier who is ready to offer after-sales support. Compliance with safety standards is also one of the factors you must consider.

About AAIT Scaffold

Since inception, AAIT scaffold has always been a leading supplier of scaffolding accessories and equipment. While we cater to diverse construction needs, we ensure safety and reliability at the construction site. When you purchase from us, you will not just be buying equipment. Instead, you will be making an investment with an assurance of successful project execution.

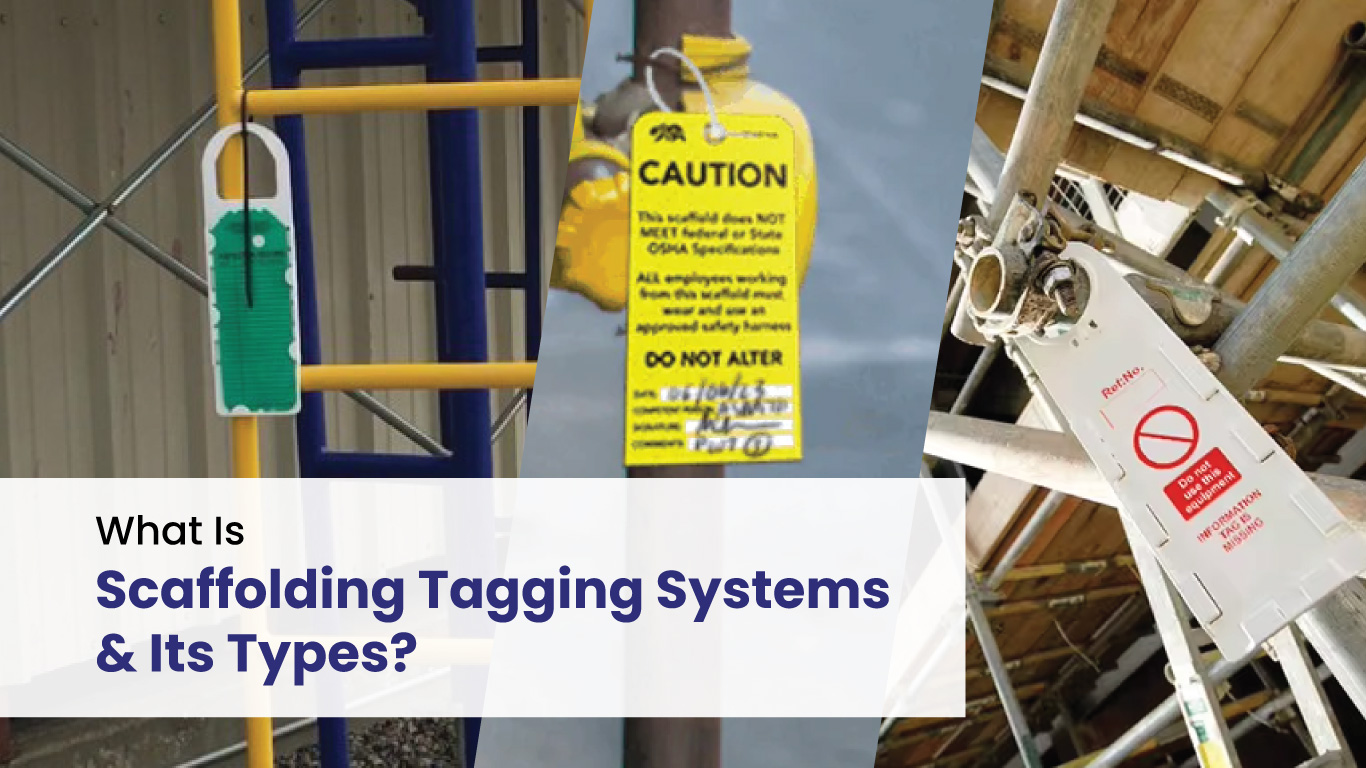

What are Scaffolding Tagging Systems & Its Types?

Comments Off on What are Scaffolding Tagging Systems & Its Types?

When you need to maintain safety at a construction site, you should always ensure that scaffolding structures are sturdy. If the structures are not strong and safe to use, then workers are likely to get injured. Hence, to prevent accidents, contractors have to use scaffolding tags soon after inspections. Once workers start focusing on their tasks, they no longer have to worry about safety. This can enable them to complete the project efficiently and with higher productivity. In this article, you will know more about scaffolding tagging systems and the types of tags.

What is a Scaffold Tagging System?

In the construction domain, a scaffold tagging system is used to ensure the safety and compliance of the structures. Once the scaffolding system is tagged properly, it enables professionals to communicate the status or relevant information. Moreover, when everyone at the construction site is concerned about safety, color-coded tags are hung to indicate the inspection results. Let’s check out more about the tags that are hung on scaffolding components.

What is the scaffold tagging policy?

Whenever scaffolds are tagged, workers have to follow certain guidelines. A unique identification number is used to identify all the tags across scaffolding components. Additionally, relevant information needs to be displayed on the tags. All the scaffolds have to be inspected after they are erected. This inspection has to be carried out according to regulatory requirements. Before the tags are hung on the components, the worker should make sure that they are in solid red, green, or yellow color. The words should also be clear so that workers understand whether the scaffold is safe to use.

Let’s check out the different types under scaffolding tagging.

What are the four types of scaffolding tags?

When you come across tags in different colors, these denote the extent to which the scaffolding is safe to use.

Green Tag

A green tag indicates that the scaffolding has been set up by an experienced professional. The colored tag, under scaffolding tagging, also signifies that the structure has passed all inspection tests and meets regulatory standards.

Yellow Tag

This tag signifies that the scaffolding has to be inspected thoroughly before workers start using it. The tag can also denote that minor issues have to be addressed before the scaffolding is considered safe for use.

Red Tag

A red tag indicates that the scaffolding is not safe to use. It could also mean that the structure hasn’t been erected properly or has some defects. Besides, the colored tag also indicates that scaffolding should not be used in any circumstances.

Blue Tag

In addition to the above tags, you will also notice a blue tag. This supplementary tag presents information related to scaffolding. This includes the load scaffolding can sustain or any relevant details.

What is the main purpose of a scaffold tagging system?

When you have to ensure safety for the scaffolding system, you have to use certain tags. While the tags provide more information about the status of scaffolding, they also indicate whether the scaffolding is erected properly. The tag also shows if the scaffolding needs to be inspected before use.

Safety Compliance

Through the use of color-coded tags, supervisors and workers can know whether scaffolding is safe to use or has to undergo maintenance.

Risk Mitigation

Once workers check scaffolding tagging, they can find out if the structure is unsafe to use. The tag systems will also reduce the risk of accidents on construction sites.

Communication

Scaffold tags serve as a helpful tool, conveying more about the status of the structure. This helps to ensure that workers and supervisors are aware of the scaffold’s overall condition. By observing the colored tag, they can also confirm whether they need to take any action.

Efficiency

With a quick assessment of the scaffolding, tagging systems can help improve efficiency. Workers can identify safe structures without spending time on inspections. This helps to save time that workers might have spent checking structural integrity.

Does all scaffolding need to be tagged?

In many construction sites, it’s mandatory to hang tags on scaffolding structures. This ensures that the scaffolding structure complies with certain safety standards. However, the need for scaffolding tagging may vary depending on the governing authorities.

Generally, the tags in different colors signify the status of the scaffolding. The colors denote whether the scaffolding has been erected safely or if it needs maintenance. This can reduce the risk of accidents when workers know which scaffolding is safe to use. On the other hand, people may not consider tagging scaffolds in certain circumstances. But it’s always considered a practice to tag structures to maintain safety.

Conclusion

Finally, we would like to state that workers have to hand the scaffold tags to the right place. They should always place the tags in locations where they are easily visible. The information printed on the scaffold tag should also be clear and easy to read. To comply with safety standards, it’s also important to inspect the structure regularly and update tags accordingly. While the information is displayed on the tags, it should include information about the inspection date along with the results.

About AAIT Scaffolds

When you’re considering numerous options for scaffolding, AAIT Scaffolds assure quality and prioritize safety. Our team is always proud to offer a vast range of scaffolding systems to meet diverse construction project needs. As soon as you go through the E-Commerce platform, you can also purchase high-quality accessories. After manufacturing scaffolding components, we test the products and ensure that OSHA standards are met. Through efficient logistics, we also offer timely delivery and dedicated support for scaffolding whenever it’s required.

How Can Scaffolding Be Made Sustainable?

Comments Off on How Can Scaffolding Be Made Sustainable?

When you’re managing a construction project, scaffolding at the site can ensure safety for workers. With essential support, workers can carry out various construction tasks efficiently. Apart from safety, scaffolding structures can help optimize workflow and allow workers to manage tasks at multiple levels. Once the scaffolding components are designed carefully, they can also ensure structural integrity, minimizing the risks of sudden accidents.In this article, we shall cover how scaffolding can affect the environment and can be made sustainable.

How Does Scaffolding Affect the Environment?

Scaffolding has both a positive and a negative impact on the environment. But the overall impact of the scaffolding structure depends on its material, disposal methods, and construction practices. Here are some ways in which such structures can affect the environment.

Resource Consumption

When materials for scaffolding components are produced, they require a lot of energy and a lot of natural resources. As soon as workers commence with the mining and drilling process, it can lead to air pollution due to gas emissions. Habitat destruction and deforestation can also be the consequences.

Waste Generation

As construction projects are executed, they can generate a lot of waste. Workers also have to think about disposing of scaffolding components if they are damaged or can’t be used ahead. But if workers dispose of components in the way it has to be done, then it causes landfill pollution and degrades the environment.

Disturbance in Habitats

Construction activities related to erecting and disassembling scaffolding structures can disturb local habitats. The disturbance can also have a negative impact on vegetation, ecosystems, and wildlife.

Risks related to Safety

If the scaffolding is not maintained or constructed properly, then it can lead to safety risks to the workers and surrounding environment. Sudden and unexpected accidents or the fall of debris can not only lead to injuries but also environmental damage.

So, with the environmental impact taken into consideration, manufacturers should think about making the scaffolding structures sustainable. On the contrary, workers should prefer erecting crank up scaffolding in addition to greens scaffolding. These have less environmental impact as the components are lightweight and reusable. However, if you manage many construction projects, then consider making scaffolding sustainable.

How Scaffolding Can be Considered Sustainable?

Scaffolding can be made sustainable when manufacturing companies design the components with the aim of reducing environmental impact. But when the team designs various components, it should consider the needs of the project. When designers keep sustainability in mind and design the components, the entire structure is known as greens scaffolding. Let’s check out how companies can make scaffolding sustainable.

Selecting suitable material

Selecting sustainable materials for greens scaffolding can help reduce the impact on the environment. Manufacturers can either use aluminum, recycled steel, or bamboo. Apart from being renewable, such materials are recyclable and have a low carbon footprint. They don’t affect the environment when compared to usual materials.

Modular Design

A modular design can enable workers to disassemble and assemble structures efficiently and in less time. In addition, the modular systems can be reused for numerous projects. Workers will no longer have to bother about using new scaffolding materials for greens scaffolding.

Research and Innovation

When sustainability is a concern, manufacturing companies should invest in the development of scaffolding technologies. The team should also use different design tools and move ahead with advanced manufacturing processes. This can help to drive innovation and promote sustainability in the construction sector.

Energy Efficiency

Through the implementation of energy-efficient practices, companies can reduce energy consumption and emissions of gasses. While the components of greens scaffolding are being manufactured, the team can use renewable energy or optimize equipment and machinery.

Waste Reduction

Reducing waste generation through efficient design and proper planning can also minimize environmental impact. While manufacturers can reuse recycled materials, they can also follow certain strategies while designing greens scaffolding.

Now, when you’re selecting sustainable materials, you first have to evaluate their environmental impact. You should only select materials that cause less pollution. Choosing materials obtained from renewable resources can also be considered. These promote sustainability in the long run because the materials can be replenished quickly.

Finally, every construction company has to follow certain practices to promote sustainability for the environment. While the project is progressing at the site, contractors should set up sustainable scaffolding structures. These will not impact the environment negatively and will also not disrupt the surrounding region. Choosing modular designs for greens scaffolding can also reduce resource consumption and the generation of waste. The structures should also be robust and strong so that there isn’t any need for replacements in the future.

About AAIT Scaffolds

By understanding the need for scaffolding, AAIT Scaffolds is always known to be the leading scaffold distributor in the US. While our team is agile in designing scaffolding parts, we assure reliability and quality for every equipment. A strategic approach also enables our team to deliver the scaffolding components as per their needs and within a certain time span.

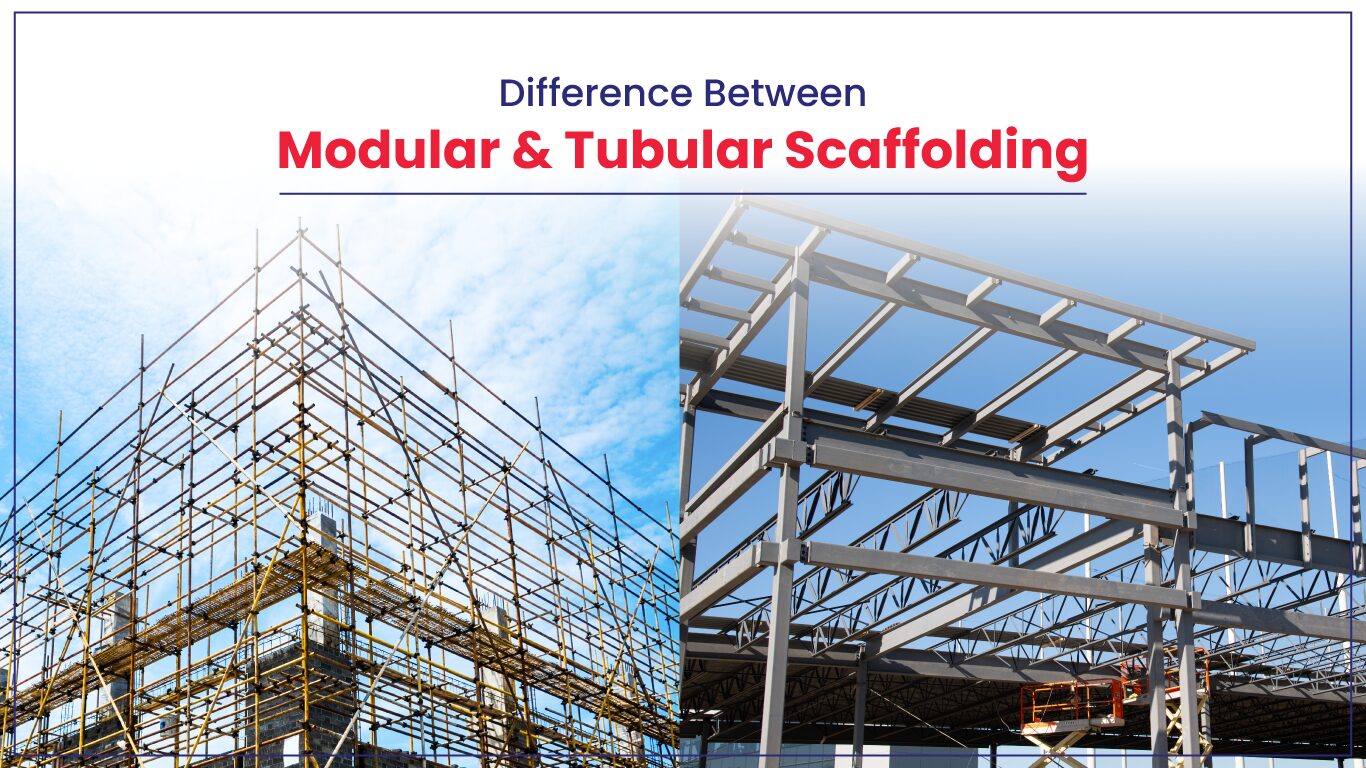

Difference Between Modular & Tubular Scaffolding

Comments Off on Difference Between Modular & Tubular Scaffolding

Introduction

Tubular scaffolding takes time and effort to set up, but it’s very versatile. You can connect the horizontal tubes to the vertical ones at almost any point, as long as you follow safety rules. Right-angle clamps hold the horizontal tubes to the vertical ones, and swivel clamps attach the diagonal tubes, making the system very durable.

Even though it’s not as popular as it used to be, tubular scaffolding is still commonly used in refineries, petrochemical plants, and power plants. It’s a flexible system that can fit almost any complex structure. While it does require more time and energy to set up, it provides the sturdy platform that many projects need.

Tubular scaffolding is perfect for projects that need to support heavy loads.

What is Tubular Scaffolding?

Scaffolding made of tubes is great for building jobs. It’s tough and useful in many ways. It is made of steel tubes that are joined together with couplers to make a strong structure that workers can use.

Tubular scaffolding, also called traditional scaffolding, tube and clamp scaffolding, tube and fitting scaffolding, or tube and coupler scaffolding, is made by connecting tubes with clamps and couplers.

You can trust that tubular supports will last a long time. The steel tubes are strong and can handle heavy loads and bad weather. Tube-shaped scaffolding is cost-effective because it can be used again and again for many jobs.

Components of Tubular Scaffolding

Tubular scaffolding is very simple to set up because it only uses four basic components:

Standards (Vertical Tubes): These are the main support tubes that run from the ground to the top.

Ledgers (Horizontal Tubes): These horizontal tubes connect the standards, providing side support and keeping the scaffolding level.

Base Plates: These plates are placed under the standards to distribute the weight and ensure stability.

Bracing: Angled tubes that prevent the structure from shifting or collapsing, making the scaffolding safer for workers.

Couplers: Fittings that connect the tubes together.

Platform: A work surface made of metal or wood, supported by transoms.

Tubular support is great because it can be used in a lot of different ways. That’s because you can change its height and form to fit your project. Tubular scaffolding is a reliable choice that can be changed to fit any job, whether you are working on a house or a big office building.

This flexibility helps construction work go smoothly and efficiently.

Difference Between Tubular & Modular Scaffolding

Modular Scaffolds

- It’s a modern type of scaffolding.

- It’s assembled using prefabricated accessories.

- It uses the tube coupling method, making it easier to assemble.

Tubular Scaffolding

- This kind of structure is common these days.

- The frame is put together with tubes.

- Setting up takes time.

- Construction teams can spend more time working on the job and less time setting up when they use tubular scaffolding. This makes them more productive overall.

- Couplers and clamps connect tubular scaffolding. Fixed joining points connect modular scaffolding, making modular scaffolding safer. In places like Israel, using modular scaffolding is required.

When choosing scaffolding, consider the job length and your budget. But safety is the most important factor.

AAIT Scaffold

Hey there! Welcome to AAIT Scaffold! We’re dedicated to providing top-notch scaffolding solutions, whether you need tubular or modular systems. No matter the size of your construction project, we’ve got you covered.

Our scaffolding stands out because it is:

- Strong: Built to handle the toughest jobs and ensure stability.

- Safe: Designed with safety as a top priority to protect your team.

- Easy to Use: Simple to set up and adaptable to your specific needs.

We support projects of all sizes, from small jobs to major construction endeavors. If you’re unsure about which scaffolding system to choose, don’t worry! Our team of experts is here to help you pick the best option for your needs.

At AAIT Scaffold, we prioritize safety and getting the job done right. Our strong, high-quality scaffolding ensures your work proceeds smoothly and securely. Our reliable scaffolding solutions support your project needs, giving you peace of mind and enhancing productivity on site.

Let’s done it together!

Benefits of Tubular Scaffolding

Comments Off on Benefits of Tubular Scaffolding

Introduction

Scaffolding is like the hero that no one sees on building sites. The strong framework holds up workers and materials as they climb to new heights to build, fix, or renovate buildings. The tubular scaffolding system is one of the best types of scaffolding because it has so many benefits. We’ll talk about why tube scaffolding is a popular choice in the building business in this blog.

Benefits

Durability:

Tubular steel scaffolding is made with tough steel tubes that are strong and treated to resist rust and damage. This makes the scaffold durable even on busy construction sites with harsh weather and heavy loads.

The great thing about these steel tubes is that they can be assembled into different types of scaffolds for all kinds of buildings—homes, shops, factories, and more. Since the tubular scaffolding system lasts a long time, construction companies save time and money on repairs and replacements. It makes everything easier and smoother on construction sites.

Versatility:

The tubular scaffolding system is great for all kinds of construction work. Whether you’re building something new or fixing something old, it’s just what you need. The best part? You can adjust it to fit each project perfectly. Construction companies love it because it saves money and gets the job done right.

You’ll see tubular scaffolding a lot on big sites like skyscrapers. It keeps workers safe while they work high up. It’s also perfect for building bridges and tunnels, giving workers a strong platform to work from.

Ease of Use:

Tubular scaffolding is easy to put up and take down. Workers can do this without much trouble, even on sites with odd shapes or curves.

This system is great for tough jobs because it’s simple to use. It lets workers move safely around a structure. If they need to make changes, they can do it easily, which is helpful for big, complex projects.

Tubular scaffolding is light and portable. A small team can handle it, making it ideal for tight spaces and large areas.

Improved Efficiency:

Using tubular scaffolding can help construction projects run more smoothly. It allows personnel and their equipment to get up high and reach areas that would otherwise be difficult to access. This means they can accomplish more in less time.

Tubular scaffolding system is also capable of supporting high loads such as building supplies and tools. Workers can move objects around more easily, increasing productivity.

Improved Safety:

The tubular steel scaffolding is designed to be extremely safe and sturdy, especially for personnel up high. Guardrails and toe boards have been erected to increase safety. These provide workers with additional protection while at work.

Tubular scaffolding system can sometimes be fitted with sound-absorbing sheets to reduce noise. This is especially useful in congested urban areas where construction noise can be disruptive. These sheets are made of a durable substance that absorbs sound. When they are installed on scaffolding, they reduce noise on the work site. This makes it less disruptive to adjacent residents and businesses. Furthermore, it improves worker safety and comfort.

Conclusion

The tubular scaffolding system is like a hero on construction sites. It keeps workers safe by providing a strong and stable platform to work on. Its sturdy design prevents accidents, making it a reliable choice for any construction project. It sets up quickly and can be adjusted to fit any job, no matter the size or complexity, which means less downtime and more productivity. The durable metal tubes are built to last, offering solid support throughout the project, even in bad weather. When you see those metal tubes on a construction site, you can be sure they make everything safer and easier for everyone.

The tubular scaffolding system is also very versatile. It can be set up in different ways to handle various tasks, whether it’s for building maintenance, repairs, or new construction. Its adaptability makes it a top choice for many contractors. Plus, it’s easy to put together and take apart, so it can be moved and reused on different sites, providing cost-effective and efficient solutions for ongoing projects.

In short, tubular scaffolding not only enhances safety and efficiency but also boosts the overall workflow on construction sites. It combines strength, flexibility, and durability to support workers and projects alike.

AAIT Scaffold

Tubular steel scaffolding is super important for construction work in the USA.

Our scaffolding accessories are tough, flexible, and easy to use, making it a top pick for construction companies. Using tubular scaffolding from AAIT Scaffolding can make your project safer and smoother.

Our team knows scaffolding well. Whether it’s a small job or a big project, we’re ready to help. We’re all about providing top-notch scaffolding that stands out.

Try AAIT Scaffolding and see the difference. Just email us with pictures and plans of your site, and we’ll get back to you.

What makes our scaffolding special? Our commitment to quality and safety. Our products meet all necessary standards and regulations, keeping your workers safe. Plus, our scaffolding is easy to set up and take down, saving you time and effort.

We also offer a range of accessories for your specific project needs. From adjustable bases to sturdy guardrails, we have everything you need for a safe and efficient work environment. Our scaffolding is durable and adaptable, fitting any construction task.

At AAIT Scaffolding, we pride ourselves on great customer service. Our experienced team is ready to help with any questions or concerns. We work closely with you to make sure you get the right scaffolding solution for your project.

Don’t settle for less when it comes to safety and efficiency. Choose AAIT Scaffolding for reliable, high-quality scaffolding you can trust. Contact us today to learn more about our products and services. We look forward to helping you achieve a successful and safe construction project.

Download

Download